When it comes to fabricating metal, most people immediately think of the automotive, airplane, or construction industry. While those sectors rely on metalworking services, steel fabricators have a much broader market reach. As an example, stainless steel fabrication plays a critical role in the coal mining industry.

Types of Projects Completed By Top Stainless Steel Fabricators in Toronto

There’s much more to the coal mining industry than you might think. Along with the miners who work beneath the surface to extract this mineral are employees above the mines that run the offices. Whether above or underground, custom sheet metal fabrication allows the creation of many things this industry can depend on.

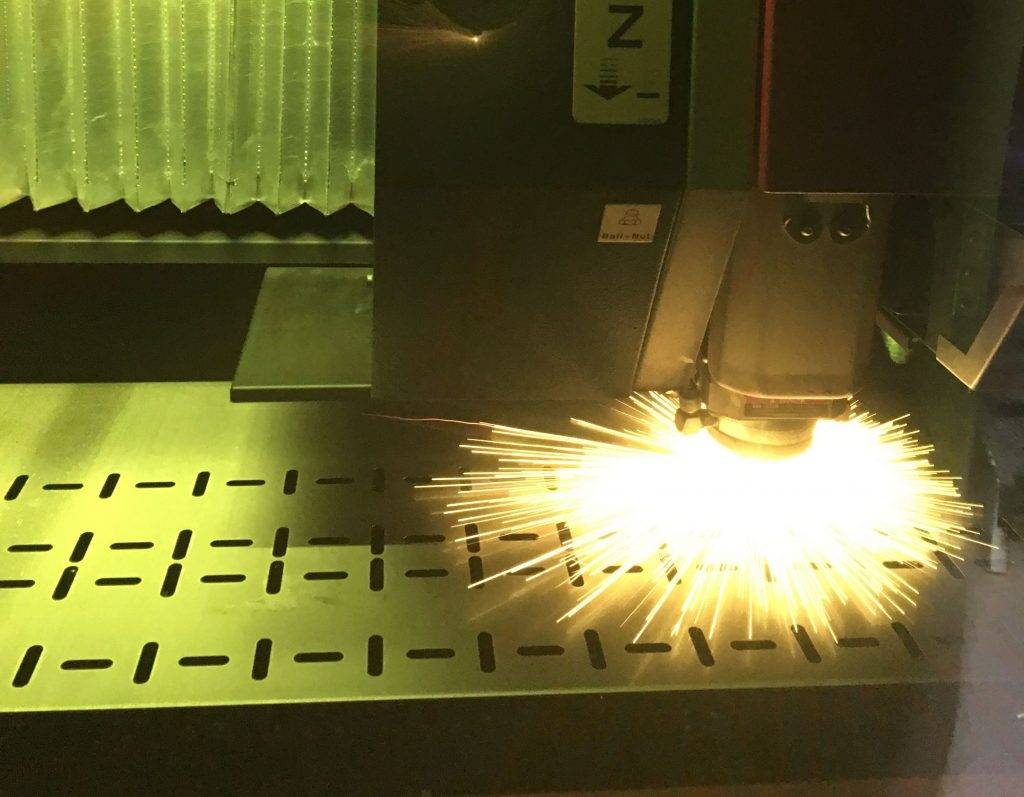

Below are examples of products made via stainless steel fabrication. Some items make the job easier and more efficient, while others enhance safety.

Handrails and Stairs

Especially for this industry, companies have to meet strict OSHA standards. To stay compliant, coal mining companies turn to a trusted source for custom sheet metal fabrication for both stairs and handrails.

The reason that customization is so critical in this case is that miners often use stairs and handrails in tight spaces to reach underground work areas. For this application, fabricators typically create products for temporary use. However, they also produce permanent handrails and stairs for offices and other buildings above ground.

Conveyor Belts

Most people don’t realize the coal mining industry uses conveyor belts. However, these as well as pulleys are common systems miners depend on. Not only do these make their work easier but, in many instances, also faster. An expert in stainless steel fabrication can create conveyor belts for miners to use throughout each phase of the mining process.

Due to the environment and materials involved, it’s important to use the services of one of the best stainless steel fabricators in Toronto. After all, to avoid problems such as corrosion, tearing, and ripping, the fabrication company must make the conveyor belts in a specific way, so they can withstand moisture and high impact.

Drifts, Mine Cages, and Elevators

For miners to reach the underground work environment, they use a cage, drift, or elevator. Miners shore up the vertical shaft of relatively shallow mines with bricks or wood. However, for deeper mines, they’ll use concrete or steel. Either way, the cage, drift, or elevator must provide workers with a safe way to enter and exit the mine. This is another example of why custom sheet metal fabrication is so important.

Turn to a Full-service Fabrication Company

As one of the top stainless steel fabricators in Toronto, Weldflow Metal Products provides coal miners with all types of precision products. We also assist with ore passes, skips, and other tasks to make work in the coal mining industry safer and more efficient. To learn more, contact us today.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com