At one point in history, there were only a few options if you wanted to cut metal. For example, metalworkers would either have to do it by hand with a saw or snips, or use a sawing or shearing machine.

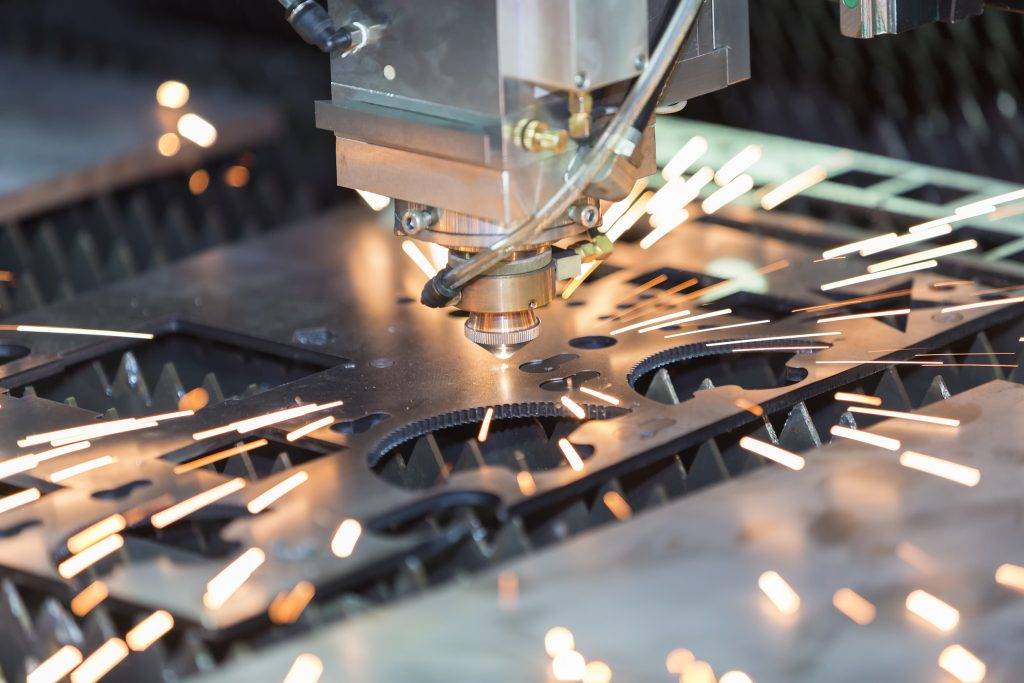

While those methods (and newer ones such as plasma cutting) are still widely being used, there’s another technology that has changed the industry – namely, laser cutting metal.

Here are some reasons why lasers are now widely being used for this application (and the benefits)…

A Cleaner and More Consistent Cut

The problem with some of the earlier methods of metal cutting is that they didn’t always produce the cleanest looking results or the smoothest edges. Not only will a laser be able to cut with a high level of precision (including creating intricate patterns), you don’t have to worry about replacing components because lasers will not degrade during operation. There’s also no warping because there’s no actual physical contact with a cutting blade.

Through Thick and Thin

Laser cutting techniques are continuously being improved. Some companies that do laser cutting in Toronto have upgraded to a fibre laser (delivered through a fibre optic cable) to get through thicker materials more easily. This also makes this method of laser cutting metal more energy efficient, as it can achieve more than traditional lasers using the same amount of power. The newer models can cut through different thicknesses of material without changing the configuration.

Leaving a Lasting Impression

A laser cutting company can do more than cut through metal – it can also use the technology to etch intricate details on a metal surface. Etching and engraving can include adding words or even artwork to the surface, which is beneficial for signage and other purposes.

Unlike some of the other methods, a computer is used to achieve precise results, and the laser cutting process is considerably faster in comparison meaning a shorter lead-time.

Useful For Many Types of Metal

While a laser cutting company may focus on laser cutting of aluminum, there are other types of metal fabrication it can be useful for as well. Fibre lasers can also cut copper, brass, stainless steel and more.

Cut With Laser Focus

The stability, versatility and speed of laser cutting have made it a more popular and cost-efficient choice for manufacturing in recent years.

Find out more about why more industries are relying on laser cutting metal from Weldflow Metal Products

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com