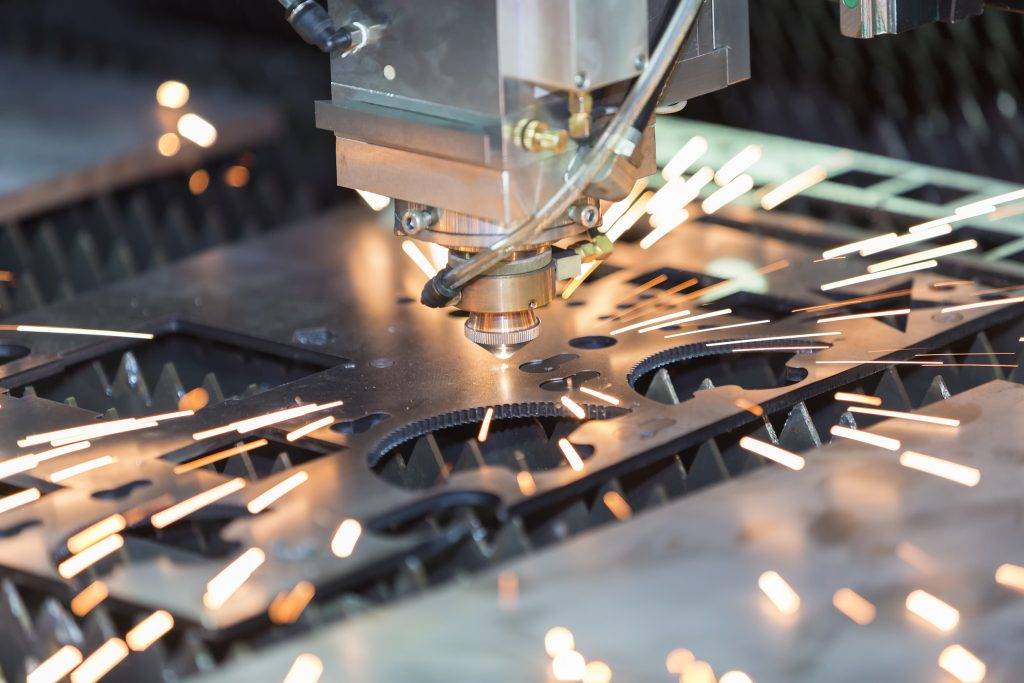

For many industries, welding plays a critical role in operations. Sometimes, it’s used to improve processes in-house. Other times, companies use welding to make superior end-user products. In some cases, traditional welding suffices but not for complex jobs. That’s when you want to rely on a leading company that provides laser cutting in Mississauga.

Key Differences Between Standard and Sheet Metal Laser Cutting

To better understand and appreciate the services that sheet metal companies provide, consider the benefits mentioned below. Keep in mind these are just a few examples.

As long as you select a reputable source for sheet metal laser cutting, the results will surpass your expectations. Below are some of the primary advantages of choosing laser welding over traditional welding.

- Focused Heat Zone – With traditional welding/cutting, the heated zone extends beyond the target area. That can damage the metal workpiece and lead to material waste. Laser welding/cutting is different. The beam hones in on a specific area. So, little to no metal outside of that sustains damage.

- Weld Strength – Whether welding something minor or complex, the goal is to achieve a maximum hold or bond. Since a laser beam is narrow, it offers a much better depth-to-width ratio than traditional welding. Not only that, but sheet metal laser cutting is stronger.

- Enhanced Precision – For tiny parts and components, traditional welding isn’t as accurate as laser welding. The beam is both small and controlled. For that reason, it performs optimally on micro-welding projects.

- Zero Contact – Here’s another reason to hire one of the top-rated sheet metal companies in Canada. Unlike traditional welding, laser welding eliminates all physical contact between the beam and workpiece material. That also helps prevent damage and waste.

- Metals – Laser welding offers more versatility compared to traditional welding. A trusted source for laser cutting in Mississauga uses more types of metals. That includes stainless steel, aluminum, titanium, high-strength steel, weld carbon steel, and even certain precious metals.

- One-sided Welding – A unique benefit of laser welding is its ability to replace spot welding. With a laser, a fabricator can access the workpiece from just one side.

- Deformation – Due to the controlled beam, parts, and components experience far less shrinkage and deformation.

Your Go-to Source for Laser Cutting in Mississauga

As you can see, sheet metal laser cutting provides tremendous benefits over traditional welding. Whether you need one simple project completed or multiple complex components, you can count on us. Weldflow Metal Products specializes in laser cutting and more. Contact us today for additional details or a free quote.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com