When it comes to metal fabrication, fiber laser cutting is an excellent way to enhance productivity. Although this technology is relatively new, it has quickly gained ground as being both a competitive and complementary cutting process compared to the more traditional technologies of CO2 laser cutting, waterjet, and plasma.

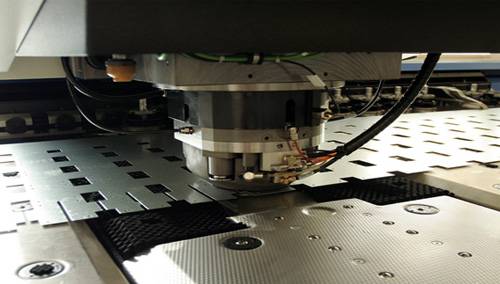

From an industrial laser cutting machine, a laser beam is generated and delivered through a fiber optic cable going to the laser cutting head. From there, the beam is transferred via the glass fiber using the quality of the beam that is customized for the cutting material. The technology and the industrial laser cutting machine combined make this a low-maintenance solution that yields outstanding results.

Another benefit of this innovative technology is that, when compared to CO2 lasers that have table size restrictions, the fiber laser is far more flexible regarding table integration. Something else to consider is that this technology is three times more energy efficient and a more cost-effective option than the CO2 technology. The cost break is especially realized when dealing with fine-featured cutting capability due to the fact that no calibration or lasering gases are required, and there are no mirrors to maintain.

As far as the fiber laser cost, this machine is more affordable to operate. In addition, this type of cutting is much easier to integrate into a broader range of cutting applications than what you would find with the CO2 technology. All of this is great, but the one aspect of cutting using fiber laser is that steel fabricators can add high-precision cutting capability, thereby achieving a far more superior cut quality and tolerance when producing fine-featured cutting.

These quality results are achievable for materials ranging from thin gauges to thick plates, and the laser cutting works great on various materials including stainless steel, brass, titanium, aluminum, copper, mild steel, and others. Simply put, fiber laser for metal cutting and welding is a much better technology than CO2, and for that reason it has become increasingly more in demand.

The fiber laser method of cutting even works beautifully on exotic materials. Considering the risk of a wrong cut on more expensive materials, this new technology puts customers’ minds at ease. Of course, it is imperative that you hire a company that is experienced in using this technology as part of their operations. Weldflow Metal Products is one such company. You can visit our website to learn more about our company and the services that we provide or contact a company representative by phone.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com