Do you have innovative ideas that you want to turn into custom cut metal shapes? If so, the best way to accomplish your goal is with custom laser cut metal. With this remarkable technique, a trusted source can make just about anything. All you need to do is provide the specifications and then leave the rest to the experts.

For a better idea of custom metal laser cutting services a reputable company offers, consider the following:

- Steel Cutting – Using high-quality raw materials, a fabricator can produce profiles in various thicknesses.

- Customization – When choosing laser for custom metal cuts, you can select from a broad range of materials. These include copper, brass, aluminum, satin coat, stainless steel, and galvanized steel. Regardless of your choice, the laser cutting service produces specialized profiles or production parts. That means you can have a profile made as part of the product that your company manufactures for end-users. It also means a top fabrication company can create detailed custom laser cut parts or components for the machinery that you use in the manufacturing process. Either way, the right company has a perfect solution.

- Custom Steel Cutting with Lasers – Although this particular laser cutting service focuses solely on parts, the right fabrication company has the capability to create specific alphabetic letters and fonts based on the specific industry. In fact, this aspect of custom laser cutting is ideal for various components or artwork.

Although many fabrication companies in Canada offer custom laser cutting services, not all produce finished products of the same calibre. Also, pricing for this type of work varies. These are two reasons why it’s so important that you do business with an experienced company. Especially when having intricate profiles or parts made, one small error could prove extremely costly.

Primary Benefits

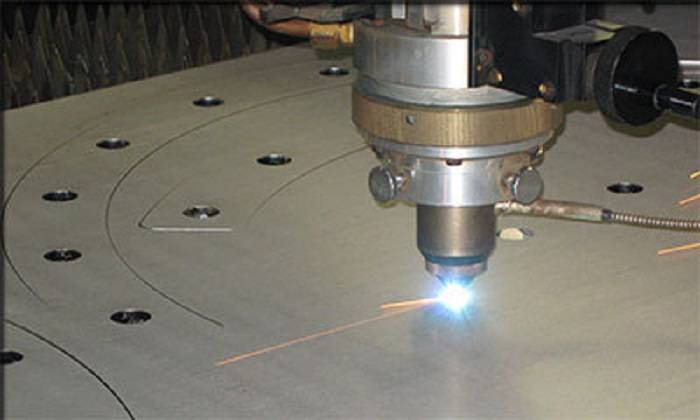

All you have to do is look at the benefits associated with custom metal laser cutting services for it to become evident that this fabrication process is an excellent choice. For starters, because a beam of light does the work, fabricators have an easier time keeping workpieces in position. As a result, that eliminates potential errors. This also prevents any risk of material contamination.

Also, this is a fast process but without compromising on accuracy. Especially if you have a rush order and precision is a priority, this is the way to go. Another benefit is that producing custom profiles and parts requires less energy compared to other fabrication methods. Because of that, the fabricator can keep its prices competitive.

Turning to a Trusted Source

For your upcoming project, we would love the opportunity to help. At Weldflow Metal Products, we provide a host of fabrication solutions, including our laser service for custom cut metal shapes. Give us a call today.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com