If your company needs to have metal workpieces cut on a frequent or daily basis or you’re expanding your operations to include metal, it’s important to choose the best fabrication services. Although many different techniques exist, there’s no question that sheet metal laser cutting produces the best results.

What You Can Expect From Professional Steel Laser Cutting Services

By turning to a trusted source for laser cutting in Mississauga, you can feel confident it uses state-of-the-art machinery and has a highly skilled team of experts. With those two things combined, you can expect fantastic results.

Below are some examples of what makes sheet metal laser cutting superior to other fabrication techniques.

Perfectly Cut Edges

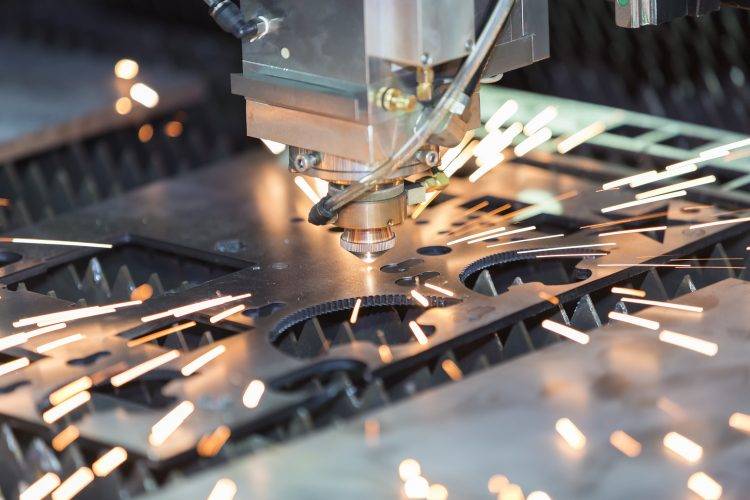

The beam used for steel laser cutting focuses on one specific area of the workpiece. For that reason, it generates less heat on the material. With a narrowed path of light, the laser produces incredibly clean cuts along the edges.

Because the laser is so small and honed in on one spot, it can produce the most intricate detailing. Regardless of the product’s shape or size, the edges around the perimeter, as well as those inside of holes and lines, are smooth and clean.

Little to No Warping

Even the best fabricators know that different problems can arise as part of the metal cutting process. One of these is warping. Not only can that delay a customer’s order but also yield wasted material. To avoid warping, laser cutting in Mississauga is the preferred choice by the top fabricator. The focused laser and processing speed eliminates the risk of metal distortion.

Amazing Customization

Most metal fabrication processes are straightforward, meaning there’s no way to customize them. However, that’s not the case with sheet metal laser cutting. With capabilities to deal with the thickness of the workpiece and the intricacy of the design, a fabricator can use this laser technology to produce a finished product to perfectly match the customer’s specifications.

Efficiency and Speed

Especially today, manufacturing and production companies face stiff competition. To stay ahead of the game, they must run an efficient operation and provide their customers with precision products on time. Steel laser cutting meets both requirements.

The exact amount of time it takes to complete a steel laser cutting project depends on various factors. These include the type of metal, the material’s thickness, design intricacy, and tolerances. However, a top-of-the-line machine can generally complete the work anywhere between 20 and 70 minutes.

Don’t Settle for Less

At Weldflow Metal Products, we’ve established a reputation for outstanding laser cutting in Mississauga. When you need metal cut with precision and speed, contact one of our product specialists.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com