Weldflow Metal Products over the years has widened its scope of services for its customers by value adding activities like engineered product development, design and production drawings using CAD/CAM applications. Our CAM application offers off-line viewing for our multi axis forming operations. These applications help us to provide for our customers’ concrete results to take decisions prior to beginning any production or developing of prototypes. This also shortens the development time.

Weldflow Metal Products over the years has widened its scope of services for its customers by value adding activities like engineered product development, design and production drawings using CAD/CAM applications. Our CAM application offers off-line viewing for our multi axis forming operations. These applications help us to provide for our customers’ concrete results to take decisions prior to beginning any production or developing of prototypes. This also shortens the development time.

As a concerted effort, Weldflow Metal Products has been striving to extend their range of services, in areas of design engineering. We have added expensive cam software like Metalix cncKad for cam applications interfacing with our CNC turret punch presses.

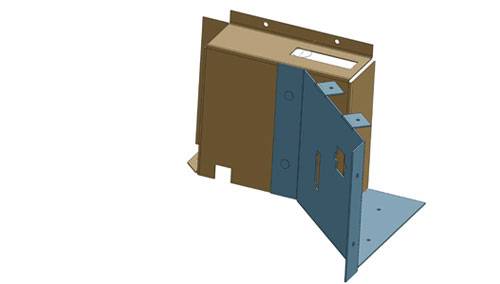

In 3-dimensional design and customer concept development process, we have SolidWorks premium version for our engineers to help provide customers with final shape of the product being developed. Thus, Weldflow Metal Products is now able to provide their valued customers with a variety of product designing engineering services. Such CAD/CAM applications, have been a catalyst in allowing Weldflow Metal Products to meet precise client specifications in the shortest amount of time possible.

Our engineering design begins from our customer providing their requirement or at times we have an existing design which requires improvement or changes due to variety of reasons. For purely two dimensional applications of production drawings we also have AutoCAD. Therefore, almost all drawing design files are compatible and can be imported or exported from our customer to us or vice versa. Weldflow Metal Products has all the latest engineering CAD and CAM tools with latest versions of software like SolidWorks, AutoCAD and cncKad, plus many more in house created engineering utility tools. This enables Weldflow team to provide best design support and quick turnaround for creating drawings for customers and thus offers an extensive array of product development related to engineering services.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com