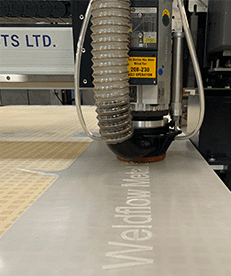

When you consider the process of CNC routing, you might think of wood or plastic materials. However, the machines can also work with aluminum, which is a softer material. Still, there are a few things companies cutting the metal need to consider. For instance, there are some intricate aspects of cutting the material. Understanding the processes many 3D printing companies in Toronto and the GTA use can help you achieve better laser-cutting results when working with these companies for the best CNC machine aluminum cutting.

About Aluminum for Cutting

The metal is “gummy,” meaning it wants to stick to the cutting tools therefore the manufacturers recommend providing a specific mist lubricant. Keeping a few things in mind will ensure that your services go well for CNC router metal cutting and milling aluminum.

Going Easy on the Material

Companies likely want to get things done as soon as they can while ensuring high quality. However, initially, it is best to adjust feed rate & RPM of the spindle a bit when removing the material. If they go too fast, they might end up with poor edge conditions in the resulting product. They do not need to adjust the speed or feed rate. However, the rate at which they remove the material should be a function of material and thickness

Ensure the Chips Get Cleared

If the machine recuts the chips, the router bits might break. Instead, consider using a vacuum dust collection system. Before re cutting the items, the workers might need to look over the things to ensure no aluminum chips are in the area.

These router tips and tricks help to cut materials such as aluminum. The information can reduce the frustration you feel. Still, remember that outsourcing the job by working with the right CNC router cutting services can also be helpful. Thus, you don’t have to worry about trying to get it right yourself.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com