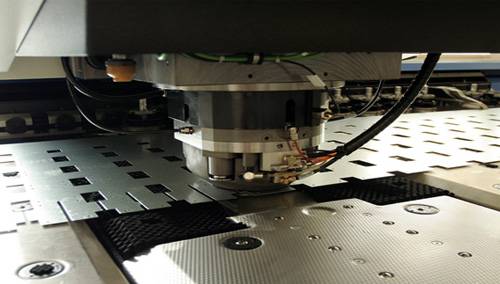

There has never been a better time to re-think manufacturing and use the latest technology to meet the needs of the industry. Experience shows that improvement is a continuous process and in that light remaining competitive will require us to embrace both innovation and change. Thus, Weldflow has recently acquired a new Fiber Laser Cutting system – ENSIS 3015 AJ from AMADA, which will complement our existing capabilities and enable us to service our ever-growing sheet metal processing needs. Furthermore, Weldflow is constantly striving to enrich its capabilities by introducing new improved ideas in engineering design by utilizing available trends in technology; implementing new leaner processes under continuous improvement strategies.

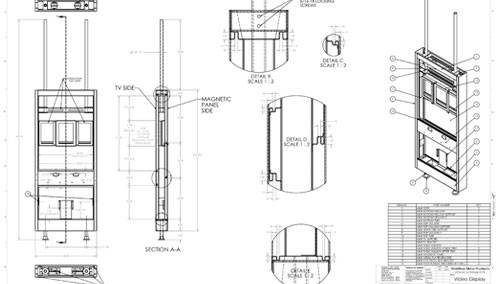

Engineering services are offered dependent upon the requirement of customers and the Weldflow technical staff is available to assist with every aspect of the design process. We can develop and prepare production drawing from initial ideas, sketches or samples.

Most of the material is stocked as inventory raw material allowing a quick turnaround.

Weldflow is equipped with the following major equipment on its production floor:

Amada mechanical shear with numerically controlled programmable back gauge can handle up to quarter inch thick plate and 10 feet long.Host of Amada turret punch presses to handle all sheet metal punch operation from simple to highly jobs. All machines are networked with computers providing loading and uploading of part programs. Most of the turret punch presses have tool setups to accommodate certain part production for a quick turn around and short response time. One machine is allocated for part development and customization process.

Different tonnage and sizes of All Steel press brakes for sheet metal forming operation. Moreover, recently added 5 Axis press brakes with offline software capabilities. All press brakes are equipped with numerically controlled back gauges.

All types of hardware insertion such as studs, standoffs, nuts special attachments are carried out through specialized automated equipment. Including the capacitor discharge welding equipment for hardware requiring clean surface on the opposite side of the hardware insertion.

All types of welding, spot welding

Weldflow has approved vendors for finishing requirements as provided by the customers, either it could be chrome plating, powder coating, anodizing or wet paint.

Engineering Design

Weldflow over the years has widened its scope of services for its customers by

value adding activities like engineered…

Shearing & Cutting

This is the first operation in our process. Depending upon the flattened part size, we could directly send a complete …

CNC Turret Punching

Weldflow has host of AMADA turret punch presses of different configuration. Ranging from

Vipros 357, Pega 345 and Pega 344….

Brake Press Forming

Weldflow has different tonnage and sizes All Steel, Ermak and

Wysung make press brakes. There are 6 different press brakes…

Tig Mig Welding

Weldflow has the capability of both TIG & MIG welding for materials like steel, stainless steel, satin coat, aluminum etc…

Hardware Insertion

Weldflow utilizes many types of hardware insertion processes, depending on

type of hardware and functionality of the joining process….

Assembly and Finishing

Weldflow has equipment related to variety of joining process and assembly of parts. These processes could employ of the process…

Inventory Management

Weldflow maintains a reputation of a quick turn around and to maintain just in time approach for our customers, it becomes very crucial…

Laser Cutting

Weldflow Metal Products has once again invested in newer laser metal cutting technology to keep up with change and continuous …

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com