Over the years, there have been tremendous changes specific to fabrication. Along with more advanced machines, fabricators now offer incredible processes. Perhaps the one that’s made the biggest difference in the customer’s products is fiber laser cutting.

Although steel laser cutting isn’t new, many people still aren’t sure how it works. If you have some knowledge of this, gaining better insight will make you appreciate sheet metal laser cutting even more. As an example, Light Amplification by Simulated Emission of Radiation, otherwise known as LASER, is a technology adopted by numerous industries and for multiple applications.

Simply put, the same laser technology that cuts through sheet metal is behind barcode scanners, devices used by law enforcement, and methods of performing delicate eye surgery. However, it’s become a key component of manufacturing. Companies around the world rely on fiber laser cutting because it’s precise and reliable.

The Way Sheet Metal Laser Cutting Works

The easiest way to describe sheet metal cutting is a device emits a powerful beam that consists of a single color or wavelength. While there are different types of laser-cutting machines, take the CO2 as an example. This particular option produces a wavelength in the infrared portion of the light spectrum. As such, it’s invisible to the naked eye.

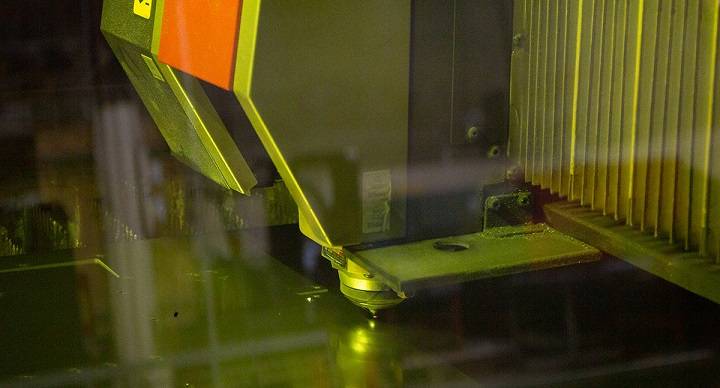

The beam that a CO2 machine produces for sheet metal laser cutting is only three-quarters of an inch in diameter. The beam itself goes from the resonator and then through the machine’s beam path. This is what creates the actual beam that cuts metal. From there, different mirrors, known as “beam benders,” cause the beam to bounce in various directions as it travels through the nozzle’s bore.

Also traveling through the bore is some kind of compressed gas, usually nitrogen or oxygen. After bouncing through the beam benders and getting pushed through the nozzle, the beam focuses on a metal plate. A curved mirror inside a special lens in the cutting head is what allows this to occur. For sheet laser cutting, the beam must focus at a precise point of the workpiece.

Once the beam locks in on its target, the full power of the laser goes through the center of the nozzle, so it can produce consistent, precise, and reliable cuts. One aspect of fiber laser cutting that makes it so exciting is that a fabricator can hit even a tiny area with extreme accuracy.

Turning to the Right Source

For sheet metal laser cutting services, it’s important to have a reputable source perform the work.

As an example, if someone without years of experience or vast knowledge of sheet laser cutting tried this, they could use a beam that’s too broad. That would cause the workpiece to melt.

For superior fabricated parts and components, contact us at Weldflow Metal Products. Our experts understand the sheet laser cutting process and, therefore, can meet your specifications.

1-866-848-3641

1-866-848-3641 sales@weldflowmetal.com

sales@weldflowmetal.com